The level sensor is a device whose switch is used to measure the material fill rate in silos, bunkers, tanks, and similar storage systems where bulk, powder, bulk solid powder, granule, materials are stored.

Silo level sensors are divided into different types according to the material to be measured and the system to be used, such as motorized rotating flag (pallet – pedal), capacitive and vibrating.

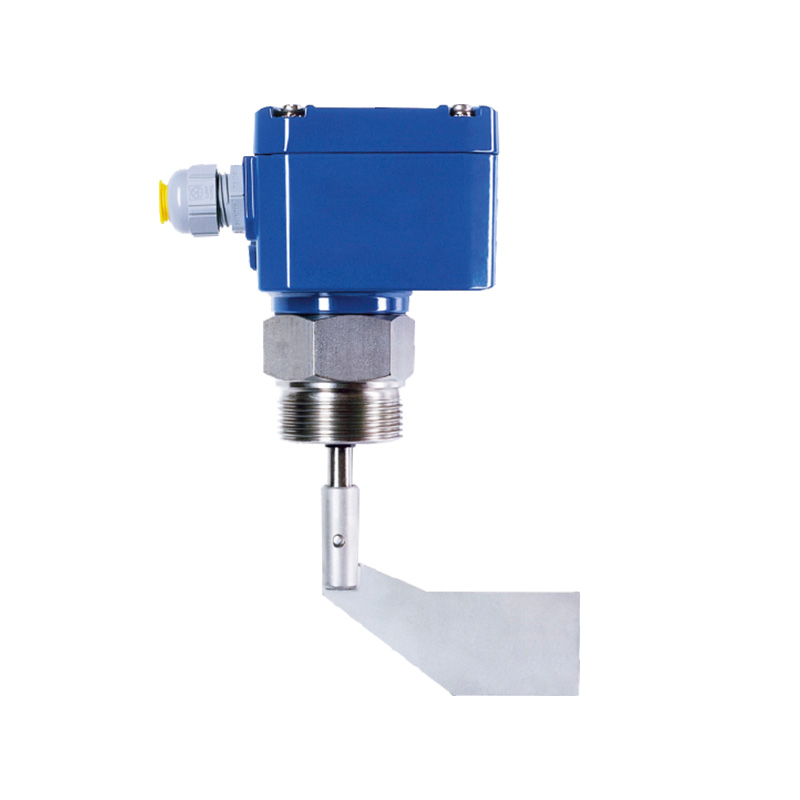

1-Motorized Flag Type Level Sensor

The flag part of the flag type level sensor that comes into contact with the material constantly rotates around its own axis, and in case the product is full or the product is empty, the motor in the flag part gives a signal when it cannot turn. All parts of the level sensor in contact with the material are made of AISI 304 quality stainless steel. silo level sensor; It can send a 24 VDC or 220 VAC signal to the automation systems of the enterprises, as well as sending an audible and light warning to the field staff (operator).

FLAG TYPE LEVEL SENSOR

2-Vibrating Silo Level Sensors

1-Vibrating type level sensors; It provides the conversion of upper and lower material levels of silo, bunker and storage systems into electrical signals by means of a vibrating fork.

2-Vibrating level sensors can be operated with 24 VDC / 50 – 60 Hz or 230 VAC / 50 – 60 Hz voltages.

3- Vibrating level sensors provide usability at a powder material temperature of 40 to 150°C.

Benefits of Level Sensors

- The sensor is easy to install

- It is economical.

- Safe measurement of bulk solids level

- Different measuring shovel types are available for every density.